Wollombi Cidery

Situated amongst the cultivated wilderness of its locale, the Wollombi Cidery project harnesses the site’s innate environmental conditions, and in turn makes them an integral part of an innovative and sustainable cider production process.

- Project.

- Wollombi Cidery

- Category.

- Research

- Client.

- Private

- Location.

- Wollombi, NSW

- Photography.

- Bradley Payne (renders)

The Wollombi Cidery concept realises a production ethos that involves growing lesser known, undervalued apple and pear varieties and marrying precise, high-tech production equipment with recycled water, site generated electricity and low waste processes across the site.

Located at the tail end of an east-west spur in the Corrabare-Watagan Mountain Range, the cidery site is bounded by steep bushland, cleared grasslands and nearby Narone Creek. Analysis of the site, its character and environmental patterns revealed the need for a winding, slow-turning path to the base of the hill and subsequent building site.

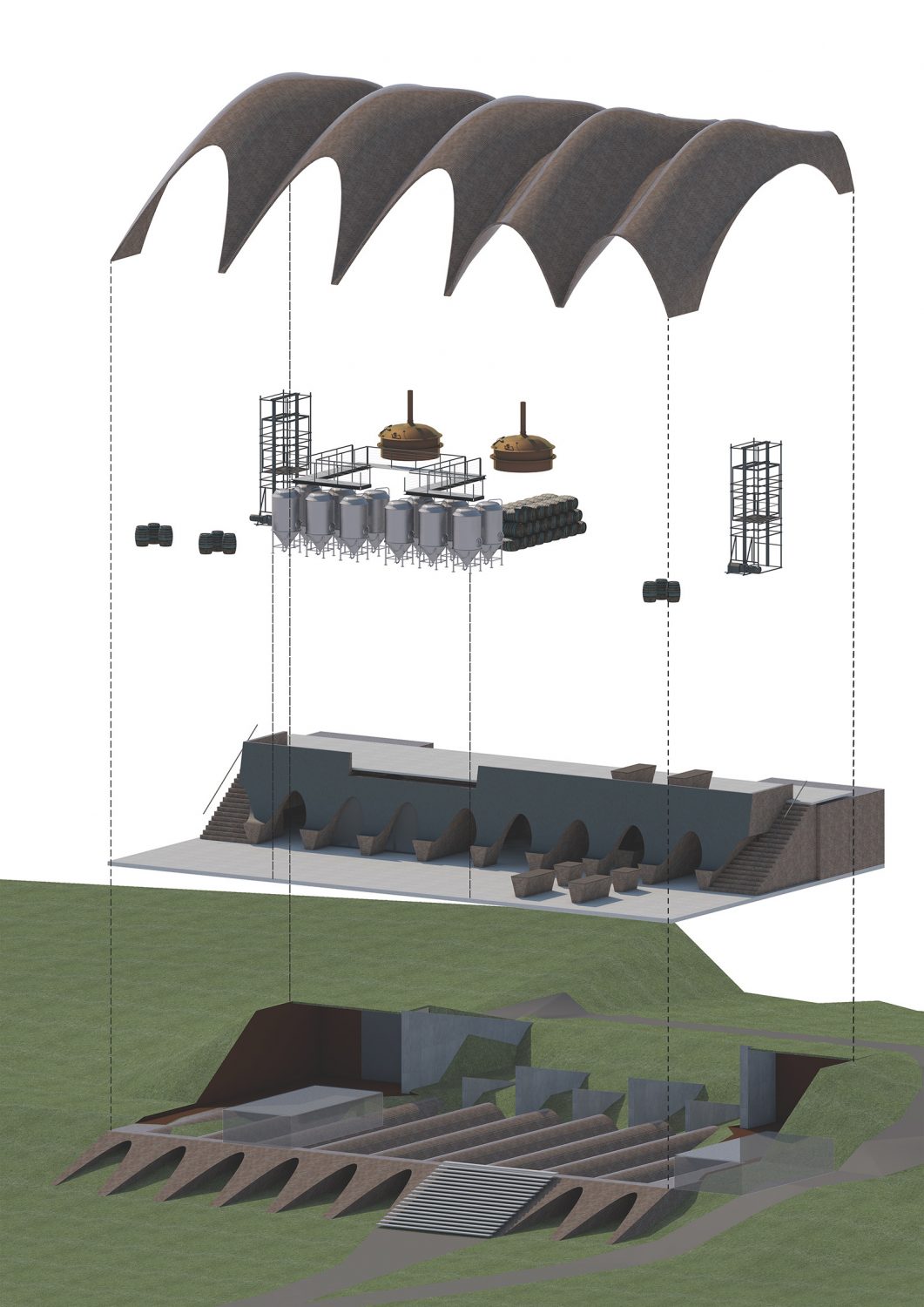

In collaboration with Julian Raxworthy Landscape Architect, a wandering pathway approach was developed, where the hilly, post-volcanic landscape is constantly viewed in all directions. In turn, these site-based musings prompted an exploration of arched forms and masonry vault construction. By adopting and manipulating the formal language of vaulting and its aesthetic capacity to reflect the surrounding landforms, the design leverages the structural economy of vaulting and the simplicity of a singular, robust material language. View the fly-through video here to experience the site.

The design therefore comprises four key elements – the vaulted platform base where seasonal flood and overland flow waters are channelled, captured and recycled for use in the cider production process and for irrigation; the tasting and production vat floor where visitors enter via the platform steps and can taste and purchase the cider, view the orchards and inspect the testing lab; the upper level production floor which allows ease of vehicular access for harvested apples and pears to be loaded into the scratters and production vats and that takes advantage of gravity feed, minimising any mechanical interference in the cider making process; and the main vaulted roof structure, draped over the functionally driven production and retail floors.